222 Palisades Creek Drive

Richardson, TX 75080

Phone: 972-952-9393

Fax: 972-952-9435

Email: [email protected]

Project: GO BaBy Go—MROC

Project: GO BaBy Go—MROC

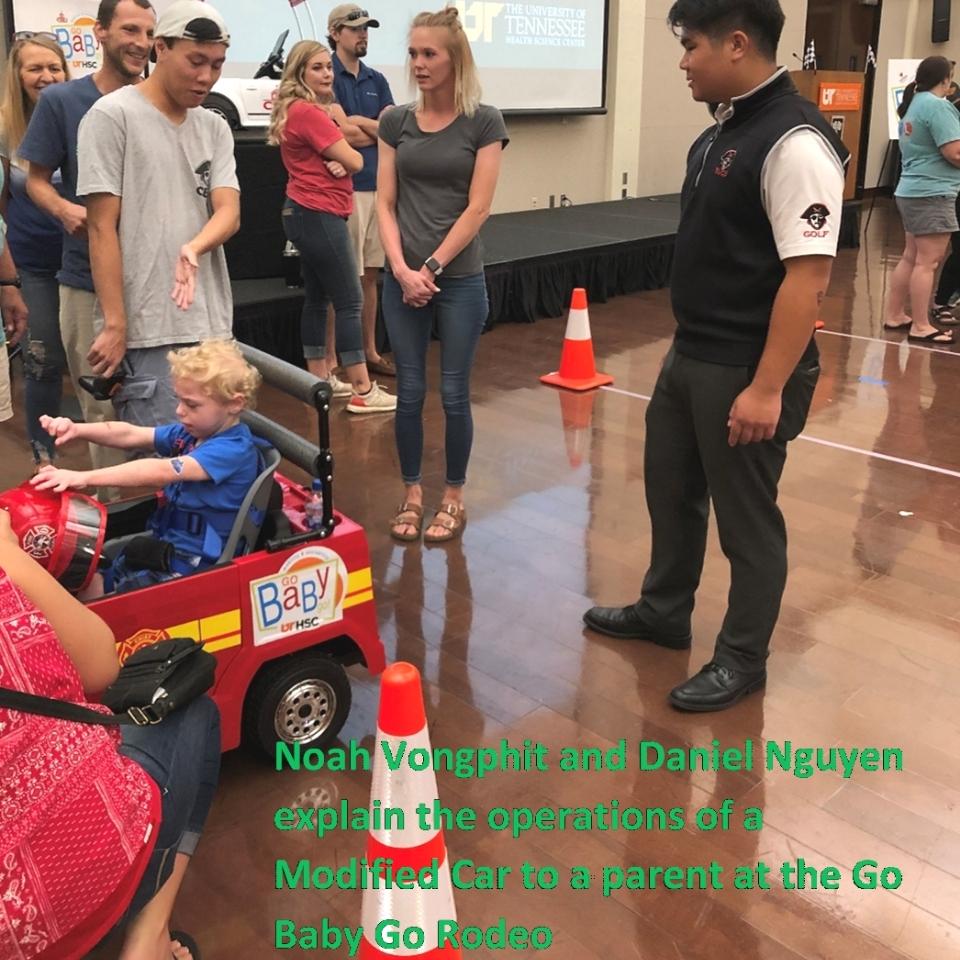

Electrical and Computer Engineering students: Steve Whatley, E.I., Judit Aubets Macia, Noah Vongphit, Daniel Nguyen, Brandy M. Washington, Felipe S. Cervantes, Jesus Flores-Valladares, Min-Seo Song, Mishal T. Alqattan, Nicholas R. Ireland, Rosemarie G. Wiethop, Stacy L. Okai, and Sylvester R. Dzimiri

Mechanical Engineering students: Melissa Tammi, Sean C. Williams, Tia C. Pearson, and Allison K. Sorette

Faculty at Christian Brothers University: Michael Sean June, Ph.D.; Chad Baker, Ph.D.; John Ventura, Ph.D., P.E.; Eric Welch, Ph.D.; Divya Choudhary, Ph.D.; Hussin K. Ragb, Ph.D.; Falih H. Ahmad, Ph.D., P.E.; James Aflaki, Ph.D.; Jose Davila, Ph.D.; Faris A. Malhas, Ph.D.; Yeu-Sheng Shiue, Ph.D.; and Siripong Malasri, Ph.D., P.E.

Faculty at University of Tennessee Health Science Center: Dr. Kunal Singhal, Luisa Ramírez de Lynch, Dr. Stephanie Lancaster, Susan E. Anderson, and Dr. Richard J. Kasser

Professional Engineers: Tim Herndon, P.E.; John Ventura, Ph.D., P.E.; Patrick McGinnis, P.E.; Falih H. Ahmad, Ph.D., P.E.; Joseph Johnson, P.E.; Frank A. Niedzwiedz Jr., P.E.; Tom Stoll, P.E.; and Siripong Malasri, Ph.D., P.E.

Additional participants: Elizabeth Hayes, E.I., Amy G. Siebenmorgen, Dr. Leslie J. McAbee, Robert Moats, Henry Rhodes, Thomas Podesta, Steve Pickett, and Renee Stoll

“The submission addressed the award criteria very well—lots of professional participation involved, including allied professions. I enjoyed that the submission explained the need for the project on a human level.”

“The public impact from this project is significant – what a ‘feel good’ project.”

“The concept and the collaboration were great.”

Having been an engineer for many years before becoming an academic, I am aware of industry needs as well as what it’s like to be a student. Students need to be able to tie the theory to something they will or may use in their careers in order for it to be valued and retained. Also, engineers must have hands-on knowledge of fabrication techniques and ergonomics to prevent the design of unworkable or complex parts that are difficult to manufacture. Early-career engineers should already know how to communicate ideas and results, set and manage expectations, work in a team environment, and be able to deliver a product on time with the highest quality practical considering all requirements. Students that have not interacted with a customer, have not brought even a simple design from ideation to product delivery, have no idea what to expect in their first job, and are at a great disadvantage.

Other programs must have a strong partnership with local industry, entrepreneurs, and inventors in order to know what is expected and needed in the world outside of the university. As well, there should be faculty with real industry experience to guide programs that foster these student experiences.

What did you like best about participating in this project?

Definitely seeing the children receive their cars and enjoying it. Knowing that our work will be used to help the children and have a lasting impact is a fulfilling feeling. It was also great to see the hard work of the team come to fruition. With this being said, the camaraderie with all the team members was also a great experience.

What did you learn?

As a team, I think one of our learning points is how we can apply the engineering principles we learned from our classes to real-world applications. We were able to take the theoretical knowledge and apply it to help the medical students and faculty create solutions for physical therapy to improve the quality of life of the children we are helping.

How did the participation of professional engineers improve the experience?

Certainly, it helped us with best practices as well as quality for long-term use. Sometimes the solutions we had were good but not the best in terms of quality and safety. For example, with a professional engineer, we were able to understand why a particular circuit layout would be better for long-term use and why a specific design may fair better with typical wear and tear. These are just tips and knowledge that is really only gained by an experienced engineer.

What do you think the engineers learned from working with students on this project?

I believe it is the different approaches to specific problems. I like to think of it as having a set of fresh eyes or a new perspective. For the engineers, I believe this is an excellent way of also learning new techniques that are being taught and reinforcing concepts. I also believe that it is an excellent experience for young engineers to learn how to advise or teach.

Elizabeth J. Hayes, E.I. is a Planning and Analytics Engineer with Fisher Arnold.

Why did you get involved with the project?

As a CBU alumna, I enjoy volunteering for my alma mater, particularly the engineering eepartment. It had such a positive impact on my life that if I can continue to help in the success of others there, I will lend my time and expertise when I can.

Additionally, I enjoy learning about new and innovative projects that young engineers have chosen. Often, it is interesting, and many times I come away very impressed at the next generation of engineers.

How did you assist the students in the project?

I attended student presentations in February and completed the oral presentation scoring rubric. I attended an online review of the project poster with Joseph Johnson, vice-president of the Memphis chapter of TSPE, in May 2021. Finally, during the IEEE EXCOM meeting, I was present when we discussed the assistance the IEEE Memphis section could provide, while setting up the Go Baby Go blog (https://gbgdatalogger.ieeecbu.org/).

What did you learn from working with the students?

I learned about the need for a Go Baby Go car for children with special needs, a little about data logging and more electronic specifics, and observed the excellent work ethic of the students at CBU.

What did you want students to learn from working with you?

Hopefully, the students could take away different innovative questions to ask during fabrication and an eye for detail on report deliverables.

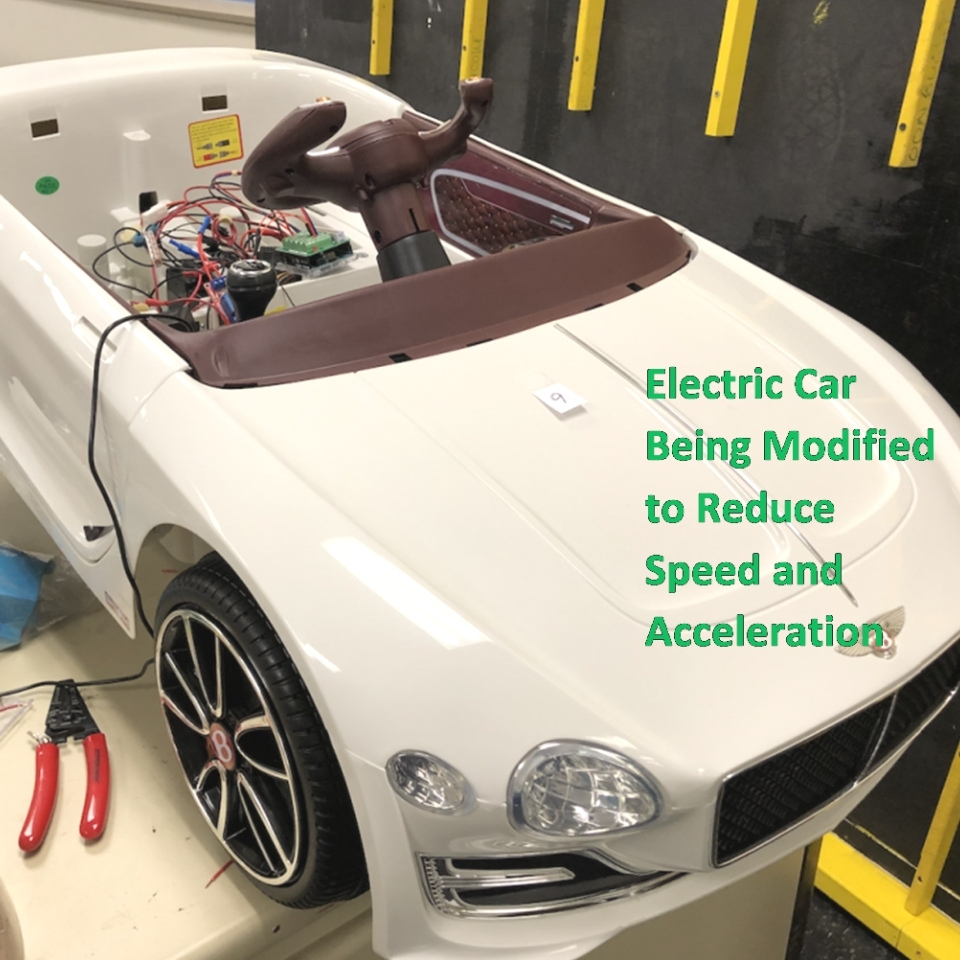

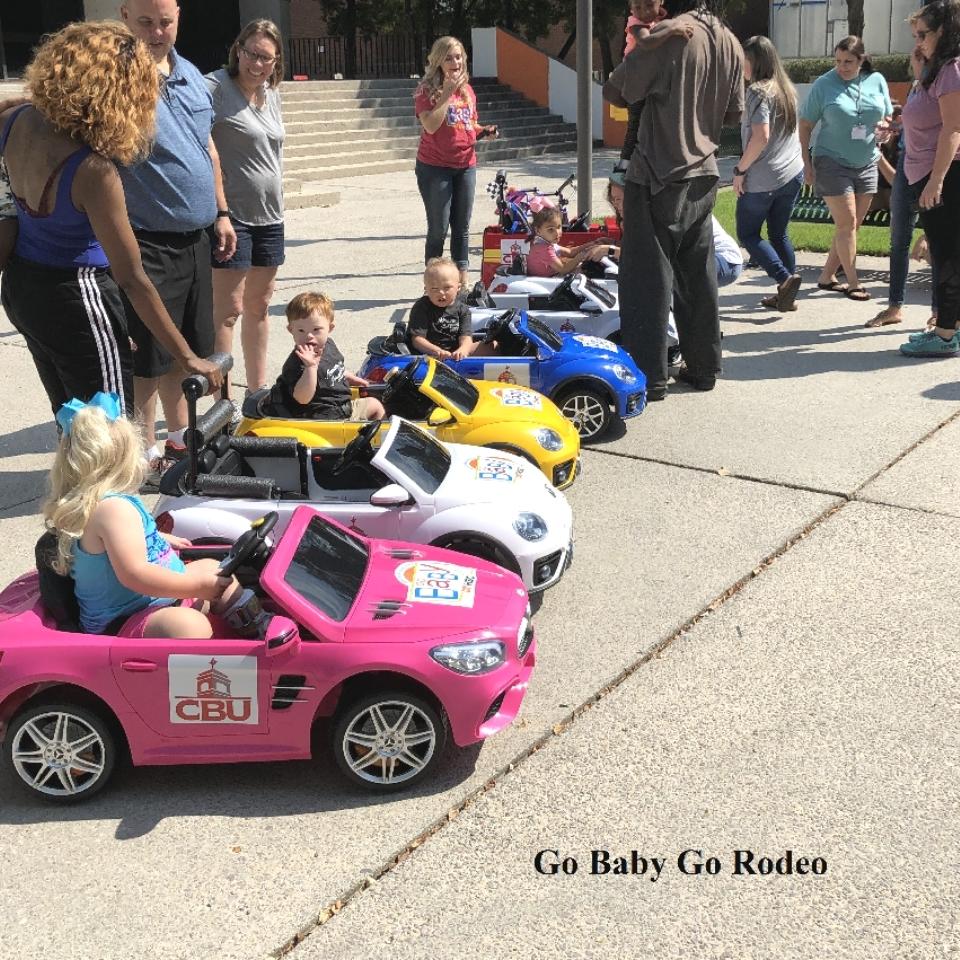

In early September of 2019, Dr. Sean June, Director of Gadomski Center for Engineering Innovation at Christian Brothers University (CBU), requested I help students who had designed a control system over the past three months to reduce the speed and acceleration of small electric cars. On September 14, 2019, a Go Baby Go Rodeo was held at the University of Tennessee Health Science Center (UTHSC) and seven children were given the cars. It was heartwarming to see the gratitude of the children and parents upon receiving the cars. The students and faculty at CBU and UTHSC displayed a tremendous sense of pride in their work and were overwhelmed by the children’s enthusiasm, as was I.

It was suggested that a test car be used to evaluate the control system and that alternated designs be investigated. The children could choose cars from different manufacturers, and that the control system would have to meet varied requirements and that cost be a consideration in all work. Students were encouraged to perform rigorous testing for the safety of the children who would exploit all features of the cars.

From March 2020 to the present, work has been limited due to COVID-19. All work has been performed remotely, and a blog was suggested for communications between students, faculty, and professionals that was operational in February 2020. Several opportunities were provided for students to demonstrate their work online to professionals and faculty. It was a delight to see the enthusiasm of the students when helping children and the willingness to work tirelessly on the project considering all that was happening to their lives to meet the online and physical requirements of the pandemic.

As part of this work, the faculty were prompted to consider that hardware and software designed to meet commercial requirements are different from those needed to complete a laboratory or course requirement. Professionals reminded students that safety was a critical aspect of their work. When work is to be part of the public domain, there is a need for a software license and an “Authorization and Release of Liability” between the universities and parents of the children, subjects not often part of an educational program.